At SKW-System, we help Canadian farmers and operators harness water’s full potential through precision, sustainability, and performance. Whether in irrigation, crop protection, or greenhouse systems, our proven German-engineered technology transforms how water works for you.

Welcome to SKW Canada

Advanced Water Technology for Agriculture & Industry

Our Mission

We are here for water — and for the people who rely on it.

Our SKW system enables the most efficient, eco-conscious use of water to support agriculture, industry, and nature. With zero chemicals and Zero maintenance, SKW improves water behavior using natural physics to reduce viscosity, boost flow, and optimize results.

Agricultural Applications

Field Sprayers

The SKW system transforms how crop protection products and water based inputs are delivered. SKW System Improves spray accuracy and increases absorption. The majority of customers have reported an increase in yield and a reduction in chemical inputs.

-

Minimum 10% reduction is required to prevent crop burning due to improved absorption

-

Better nutrient and pesticide uptake = healthier crops

-

Lower pressure in spray lines = higher flow and efficiency

-

Less rinsing water required when switching agents

-

No scaling or clogging in pipes and nozzles

Key Benefits

Field Irrigation

Maximize Yield. Minimize Waste.

SKW revolutionizes irrigation with more even distribution and optimized plant response.

-

No waterlogging or puddling

-

Shorter run times, faster drying

-

Increased yield per square foot

-

Better root development and faster crop growth

-

Fewer biofilms, mineral build-ups, and algae

-

Improved nutrient uptake and fertilizer efficiency

-

20% faster hose intake speeds

Key Benefits

Greenhouse & Vertical Farming

Oxygenated Roots. Uniform Growth. Less Maintenance.

In controlled environments, SKW leads to stronger roots and more consistent yields.

-

Reduces biofilm and calcium build-up

-

Improves oxygen delivery to roots

-

Enhances absorption of nutrients

-

Minimizes system clogging, ensuring **100% irrigation performance

-

No scaling or clogging in pipes and nozzles

Key Benefits

Animal Drinking Systems

Healthier Livestock. Cleaner Systems.

-

Improved feed utilization and metabolism

-

Lower veterinary costs

-

Reduced ammonia load and improved stable air

-

Eliminates biofilm in troughs and water lines

Key Benefits

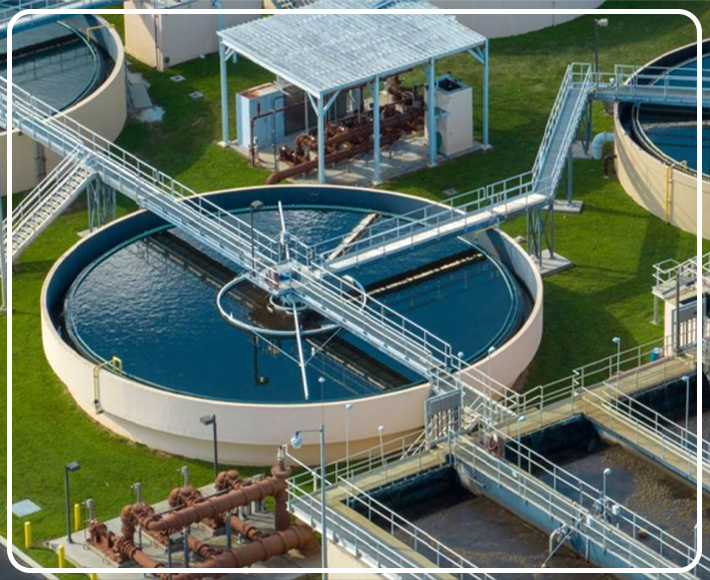

SKW Canada – Engineered Water Solutions for Industry Reducing Resources.

Increasing Revenues.

SKW® Canada delivers German-engineered water treatment systems trusted by global leaders like Boeing, Airbus, and Royal Marine Bahrain.

Proven, Certified, and Ready for Harsh Environments

- Aerospace-certified (ATA 38 drinking water systems) - Installed globally in high-demand sectors- Maintenance-free, chemical-free, and cost- efficient

Why Oil & Gas Operations Trust SKW®

Efficiency, uptime, and reliability are everything in oil and gas. SKW® delivers measurable gains in performance and cost reduction. Operators use SKW® to:- Prevent scale and biofilm in cooling circuits, vacuum systems, and water injectors- Reduce or eliminate the use of corrosion inhibitors, anti-scaling agents, and biocides - Extend service life of membranes, heat exchangers, and pumps- Cut downtime and cleaning cycles- Maintain optimal system flow, even under harsh conditions- Operate sustainably, without chemicals, waste, or discharge permits

Refinery Applications

In refinery operations, maintaining peak efficiency in cooling and process systems is essential. Refineries often battle heat exchanger fouling, scale formation, and biofilm—common in units like debutanizer overhead condensers, wet gas compressor inter- stage coolers, and produced water treatment systems.

Where SKW® Adds Value:

buildup (e.g., calcium carbonate, sulfates) that compromise heat exchange efficiency and cause leaks- Improve Produced-Water Systems: Combat fouling from oil residuals in sour water treating and flotation equipment- Reduce Chemical Load: Minimize reliance on antiscalants and corrosion inhibitors in cooling towers and process loops- Extend Run Times: Longer periods between shutdowns and heat exchanger cleanings—supporting strategies like heat exchanger network optimization- Mitigate Microbial Corrosion: Address biofilm in dead legs and low-flow areas to prevent microbiologically induced corrosion (MIC)

Process Areas with High Impact:

- Debutanizer condensers- Wet gas cooler exchangers- Produced water separators & sour water strippers - Cooling tower circuits- Wastewater and blowdown treatment loops

Other Industrial Applications Across Canada

SKW® systems are already proven in:- Cooling towers (open/closed)- Heat exchangers & chillers- Evaporators, CIP systems, UHT units- Breweries, dairy plants, pulp & paper mills, aluminum casting - Marine & offshore cooling systems - Sewage and biological treatment facilities These systems help industries reduce water chemistry costs, eliminate mineral buildup, and cut energy use — all while improving uptime and yield.

Why Choose SKW Canada?

-

Over 35 years of proven results

-

Made in Germany, adapted for Canadian agriculture

-

No chemicals. No moving parts. No external energy

-

Trusted in aviation, greenhouses, farms, and food systems

-

Committed to reducing resources and increasing profit

Our Videos

.jpg)

How It Works

Water Optimization Through Natural Physics

The SKW® system uses the Lorentz force to restructure water molecules, lowering viscosity and internal friction. This improves water’s behavior without chemicals or power, allowing:

- Greater flow rates

- Better distribution

- More efficient heat and nutrient transfer

- Less scaling and fouling

Contact with us

Contact form